Element Six – HPHT (High Pressure High Temperature) PCD・PCBN・MONO for Machining

Cutting tool applications

E6 Polycrystalline Diamond PCD / Polycrystalline cBN – PCBN / Large Single Crystal Diamonds (MONO)

E6 manufactures and sells a variety of diamond and cBN cutting tool materials used for machining in automotive, aerospace, drilling for oil and gas and in ultra-precision machining applications of semiconductor components and optical components.

Copyright Element Six

HPHT synthesis is a method of synthesizing diamonds by mimicking the conditions of nature.

High pressure is generated by concentrating hydraulic force on a small area.

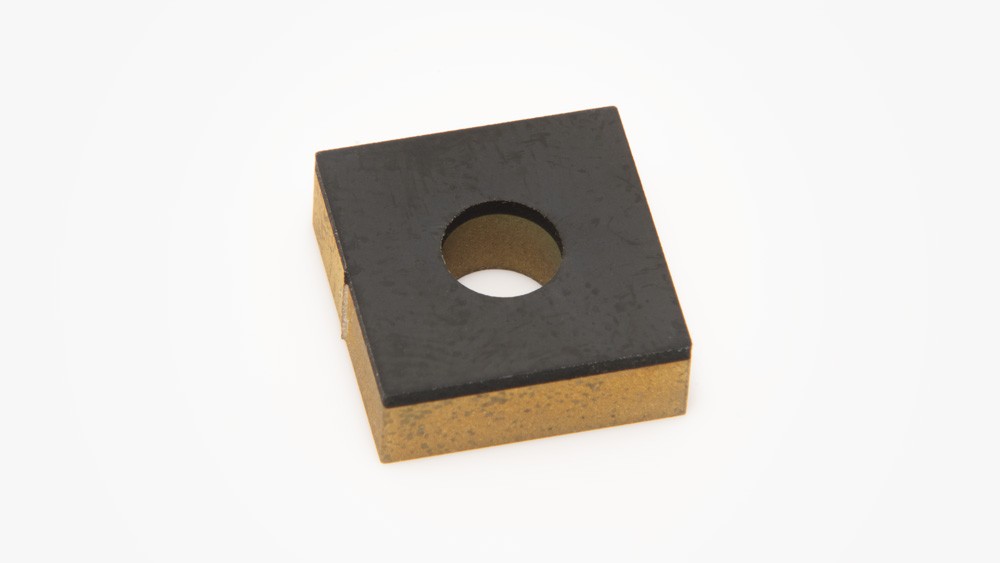

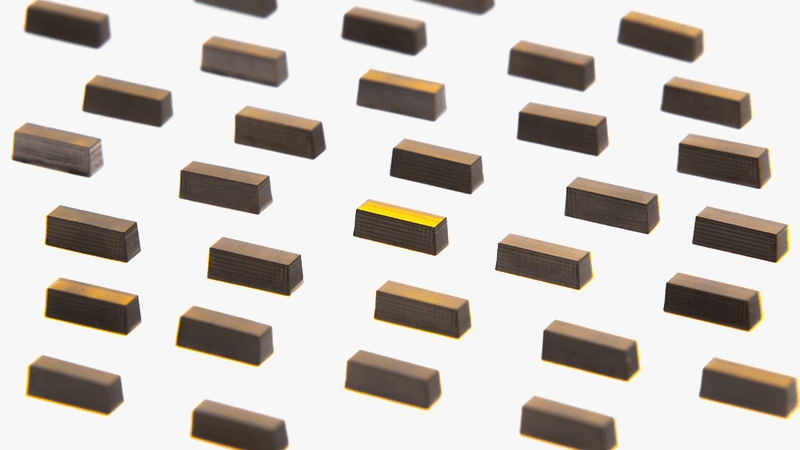

Diamond grains intergrow to form PCD and PCBN under high pressure and high temperature. They are widely used in various industrial applications such as machining, cutting metal milling, turning, drilling and reaming and oil and gas drilling.

At high temperatures and pressures, carbon atoms dissolve into molten metals such as iron, cobalt, and nickel to synthesize large single crystal diamonds (MONO). It is used for a variety of applications such as milling, drilling, abrasion-resistant parts, and wire drawing dies.

PCD (polycrystalline diamond sintered body) is cutting of a wide range of non-ferrous metals. These synthetic diamonds excel at cutting aluminum, wood, and even composite delicate plastics without clogging. PCD also processes brittle materials such as glass due to its resistance to chipping and abrasion. The result is clean cuts, longer tool life, and reduced downtime due to blade changes.

With its ultimate sharpness, monocrystalline diamonds (MONO) provide ultra-finished cuts to delicate workpieces. Unlike polycrystalline diamonds, it is a single perfect diamond crystal. It provides unparalleled precision for mirror-finishing smartphone aluminum, polishing perfect lens molds, and creating complex molds. The result is an excellent surface finish, minimized wear and extended tool life for these demanding applications.